A gear motor refers to an integrated assembly of a speed reducer and an electric motor.

A gear motor is a device that converts a high-speed motor into a low-speed high-torque output one. It is widely used in various fields, including industrial manufacturing, transportation, home appliances, etc. According to different working conditions and requirements, there are many different series of gear motors available in the market. The series of gear motors introduced in the following are commonly used.

- Planetary Gear Motor

Planetary gear motor is a kind of compact gear motor with high output power and high torque. It adopts the principle of planetary gear transmission, which has the advantages of high efficiency, high precision and low noise. Planetary gear motors are commonly used in automation equipment, mechanical transmission, precision instruments, etc.

2. Spur Gear Motor

A spur gear reducer utilizes spur gears for transmission and is commonly employed in applications requiring the transmission of torque and angular velocity. It is characterized by compact size, high reliability, and efficient transmission. Spur gear reducers are used extensively in such industries as metallurgy, petroleum, chemical, and mining.

.

Power: 40w

Voltage: 110v, 220v, 230v, 380v

Ratio: 3:1 ~ 500:1

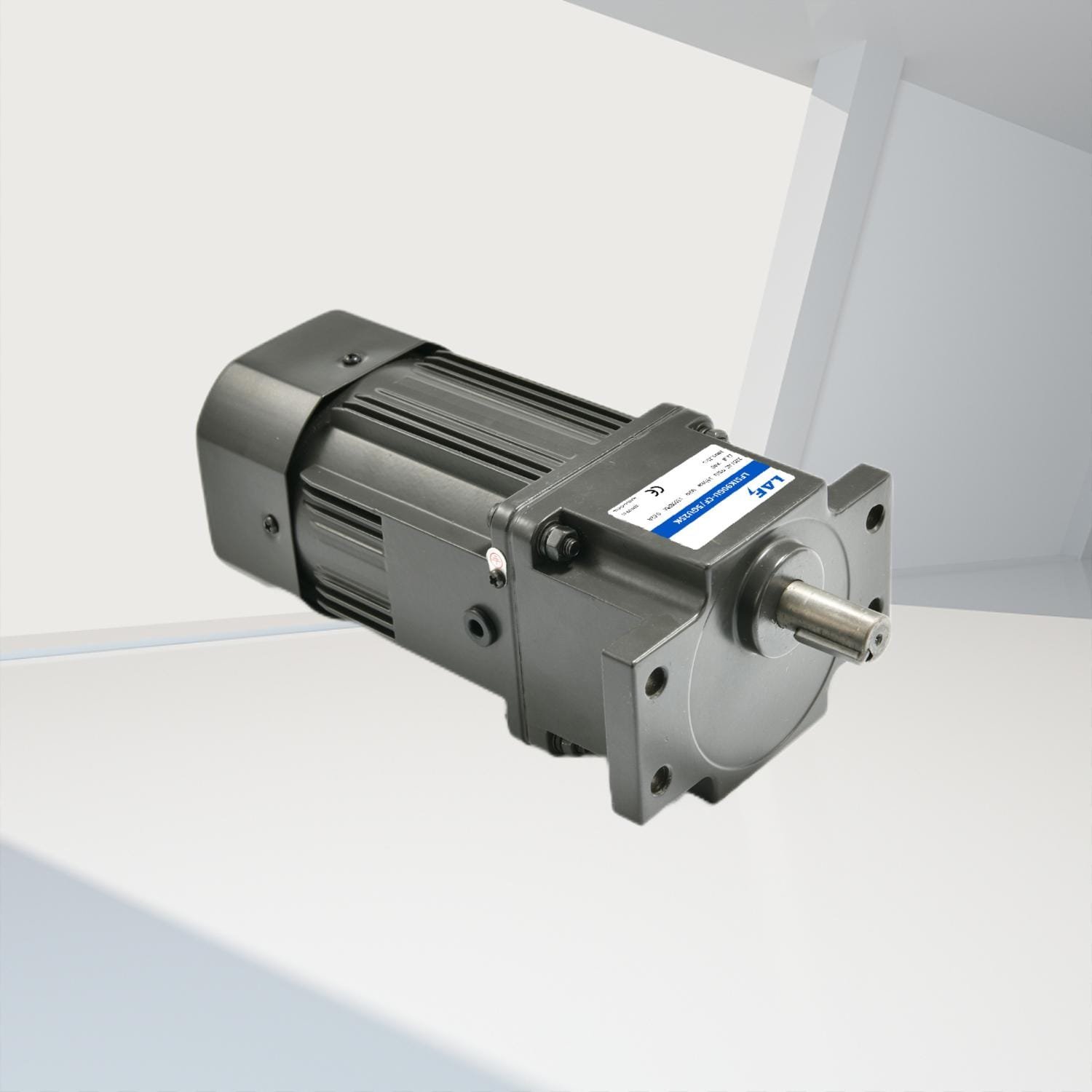

Model: LF5IK90GU with mounting ears

Power: 90w

Voltage: 110v, 220v, 230v, 380v

Ratio: 3:1 ~ 500:1

A parallel shaft helical gear motor is with a simple structure and high transmission efficiency. This type of motor is commonly used in various industrial applications requiring medium to low power, high speed ratios and high precision transmission. Parallel shaft helical gear motors are commonly found in industries such as manufacturing, textiles, and printing.

- Cylindrical Gear Motor

A cylindrical gear motor uses cylindrical gear transmission, and is characterized by high torque and smooth transmission. It is suitable for transmission needs with medium to small power and low speed ratios. The cylindrical gear motor is widely used in industries such as food processing, textile manufacturing, and packaging equipment.

- Cone-disc Gear Motor

A cone disc gear motor is with a simple structure and high reliability. It uses a cone disc and slip ring resistor to achieve the speed reduction. Cone-disc gear motors are suitable for low power, low speed ratio transmission needs and are commonly found in mixing equipment, refrigeration equipment, and so on.

It is important to note that the selection of a gear motor should be determined based on specific working conditions and application requirements. Different series of gear motors have different characteristics and applicable ranges. Therefore, it is necessary to comprehensively consider factors such as power, speed, and torque in selection to ensure that the selected gear motor can meet the actual needs.

Add comment